Plasma Water Table Journey #3

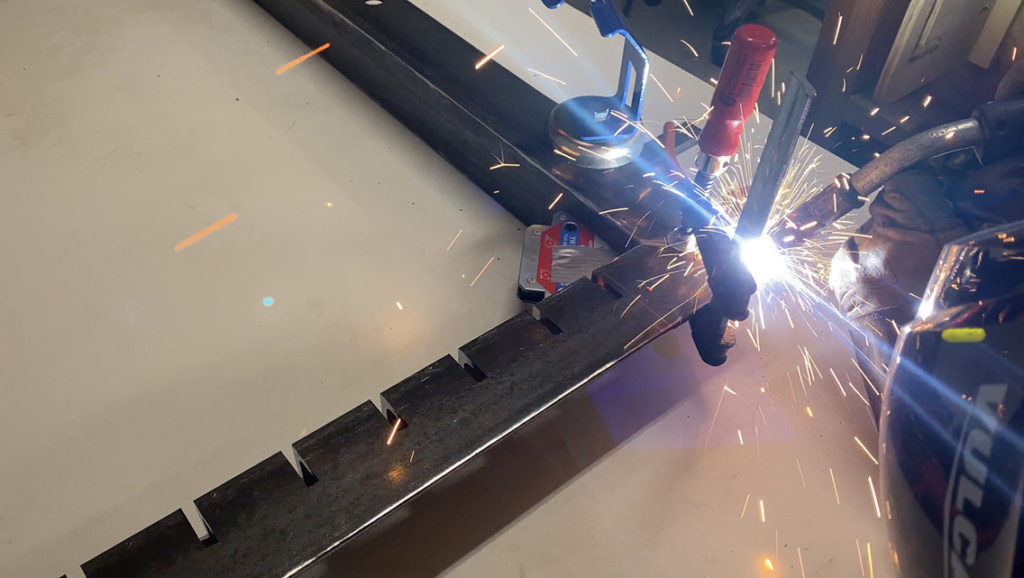

It was a very eventful “Day 3″ to say the least. I started to weld and realized I was out of gas. Only that was half the problem. I get home, hook up the gas and the welds still looked like birdy doody. Turns out my connecter feeder knob was loose. I have no clue how that happened, but that would explain a lot of terrible looking welds. Now my confidence has gotten a big boost. I proceeded to double check my bevels and sure enough I didn’t go as deep as I should’ve. I got to where there was about 3/16” of an inch at the base of the bevel.

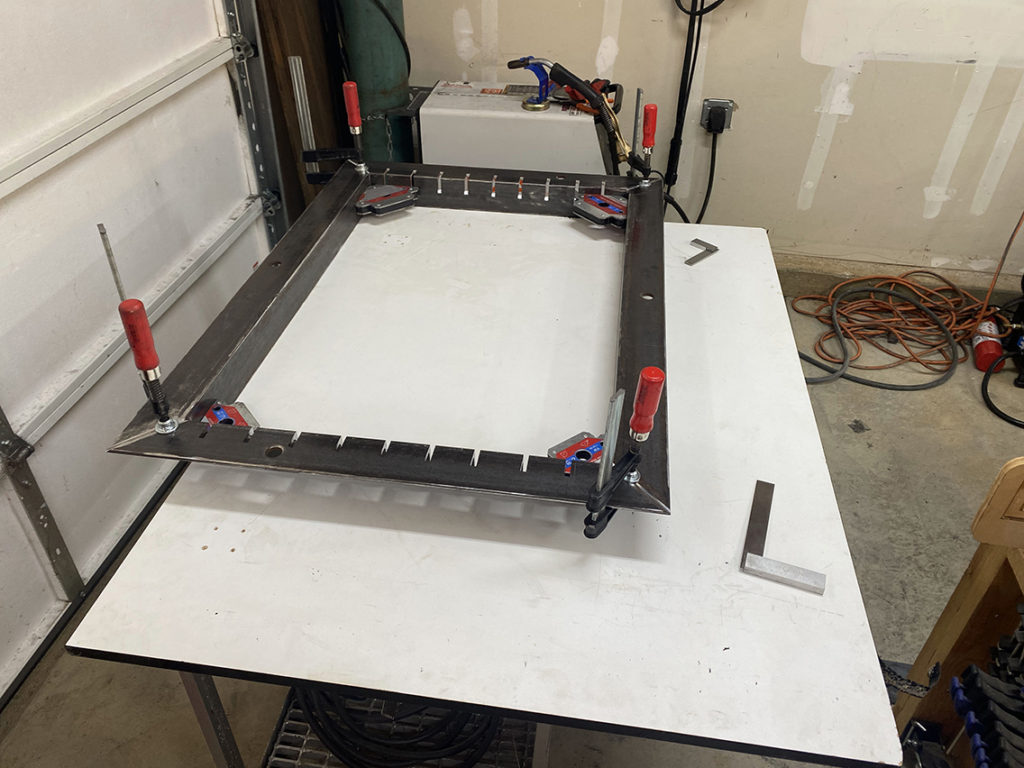

I think that would be good for proper penetration. Again, I’m using 1/4″ material. After getting all my miters squared, I placed the top frame on a flat surface.

I did some tack welds to start off with. I then took the clamps off and finished the rest of the welds.

It came out as good as I could get them. I’m so thankful for flap discs so I could smooth out all my newbie welds.

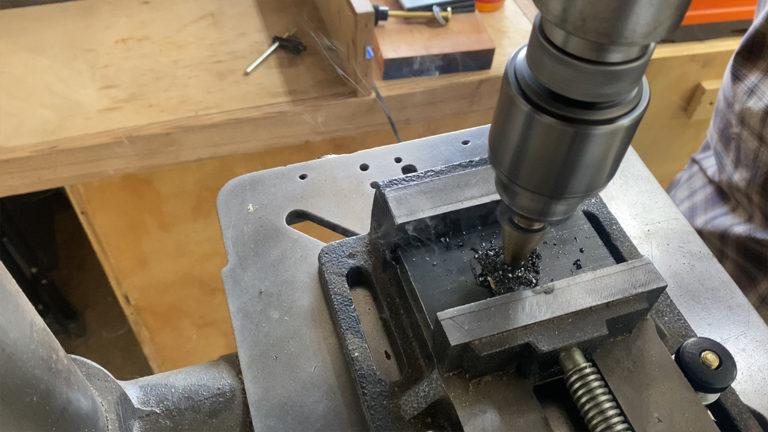

After the welding, I wanted to cut all the slats out. So I fired up the Evolution S380-CPS and went to work.

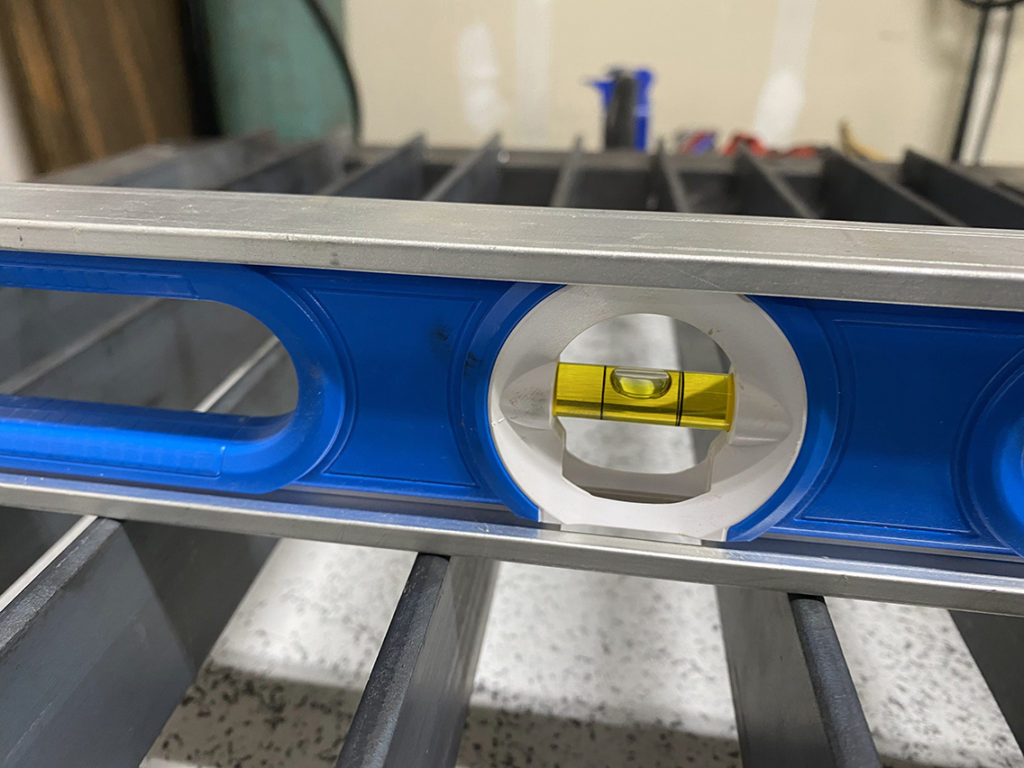

Surprisingly, the depth stop that I set up on the Evolution S380-CPS when cutting the slat slots was consistent all the way across both ends. So all the slats sit at the same height and are level. I was pleasantly pleased with that!

After all that transpired today, I just sat in my shop staring at this new creation I made. It amazes me how the human spirit has the audacity and fortitude to push itself into new adventures. I call mine a journey. And on a journey you should enjoy it. It isn’t all about the destination as much as the journey. So today, I was greatly pleased at the results. My confidence is much higher. My skills are increasing. It’s a “win win” if you ask me. Have a great day!

Glad to see dreams coming to fruition

Thanks brother!