Plasma Water Table Journey #5

In any project I’m sure you all have visualized what, and how you were going to do the next step. Waiting for the casters to come brought some anxiety. So when the casters came in today, I could finally finish what had been playing over and over in my head.

I started out measuring the caster plates to where they would be an 1/8″ shorter than my leg base so there would be a lip for good welding. Then, I fired up the Evolution S380-CPS and made the cuts. I ended up using the cut off scrap from the 1/4″ slat material. So it was perfect because I thought I was gonna haft to plasma cut some more tubes.

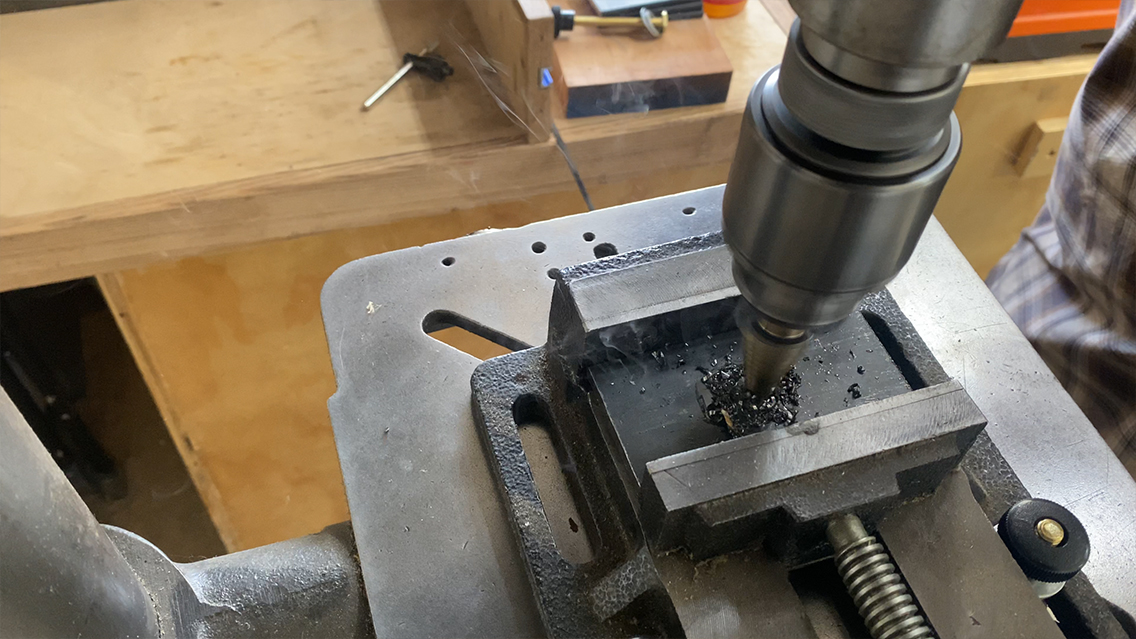

Next, I went over to the Atlas Drill Press and drilled out 1/2″ holes on center for the 12mm stems of the casters. I used a step drill bit that I purchased from Banggood, and it worked flawlessly. Here is a good one I found on Amazon that is comparable. I used some Tap Magic cutting fluid to assist the drill bit.

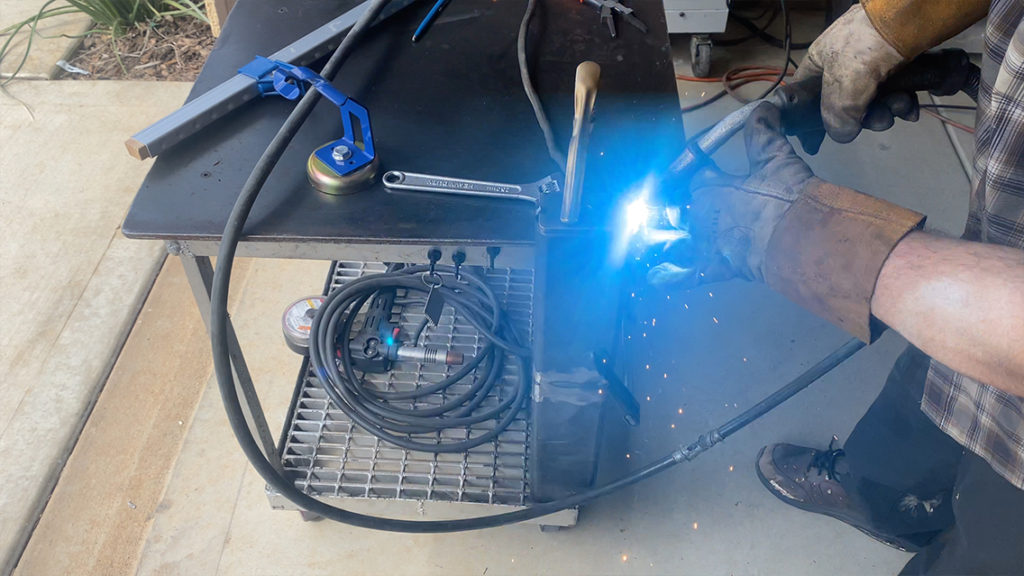

After the plates were drilled, I setup my Hercules bench grinder and rounded the corners of one side of each plate. This was more for aesthetics than anything. With the aforementioned 1/8″ lip exposed, I tacked, then welded each of the plates on all the legs.

I placed each leg on a corner and used square magnets, a machinist square, and a bubble level to get some kind of uniformity. I noticed that the corner of the l frame steel that I was using was rounded and the sharp corners of the legs didn’t want to sit flush against the side wall. So I took my angle grinder and rounded the inside corners of each leg so they would sit flush with the side wall.

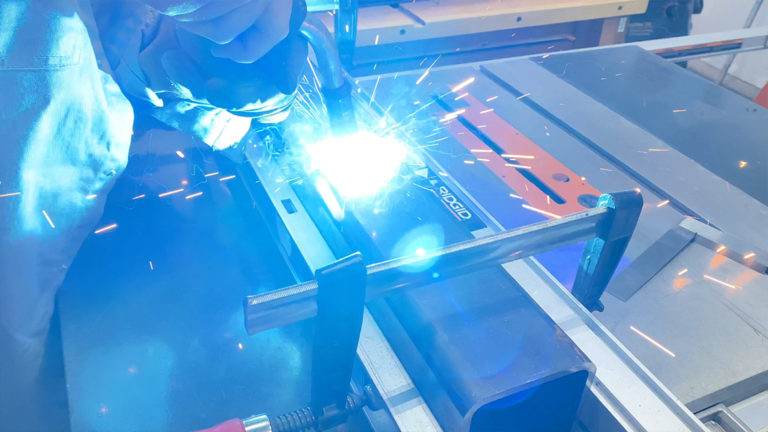

I tacked and welded all the way around and up the leg. All this welding is giving me good practice. So far I’ve had about 30 minutes of total practice. They are rough looking welds but they work!

After welding the legs, I cleaned up the welds as best as I could with a flap disc and installed the casters. These casters are by MOLIGOU and are a good value for what you get. With a rating of 2200 Lbs, these will be perfect. They also have the ability to level the table and move it around. I’m very happy with them.

After the casters were installed, I slid the plasma table frame over to the edge of my welding table and flipped it over. I then scooted it over until one side’s casters touched the ground, then worked my way till it was off the welding table. This thing is heavy! But it’s good and is the perfect height to use with my welding table for the ArcDroid CNC Plasma Robot. I’m thinking about saving up and getting one. But that will be a while. Meanwhile, the plasma water table is coming along and I’m very pleased with the results. I put a bubble level on the plasma table frame and it was dead center. I’m so pumped about this. Because the water reservoir needs to be level of course.

My next step is to weld the cross pieces and rails to slide the water reservoir in and out if needed. I also want to put two center cross supports for the bottom of the reservoir. I figured that 36″ x 24″ x 6″ was roughly 70.50 gallons which equates to 588.40 Lbs of water. That’s a lot of weight and needs to be supported properly. Thanks for checking in. I will probably do that on Monday because Saturday is a family/friend day. Have a great weekend!