PrimeWeld Cut60 Plasma Cutter

As I slowly add more tools to my shop, I’ve decided to take on another trade in regards to metalworking.

I started out with a Hobart IronMan 230 Mig welder, and now I’m acquiring various tools that are involved in the metalworking trade. It’s exciting that I’m getting to do this stuff in my garage versus some trade school or jobsite.

Back to the tool, the PrimeWeld Cut60 is an incredible tool! I was able to get it setup and working on the same day.

Of course I used the Nanpu Air System legitimately for the first time and it worked quite well. This being the best option to save money on consumables.

Be sure to check that episode out if you missed it.

The build quality and over all manufacturing are top notch in my opinion.

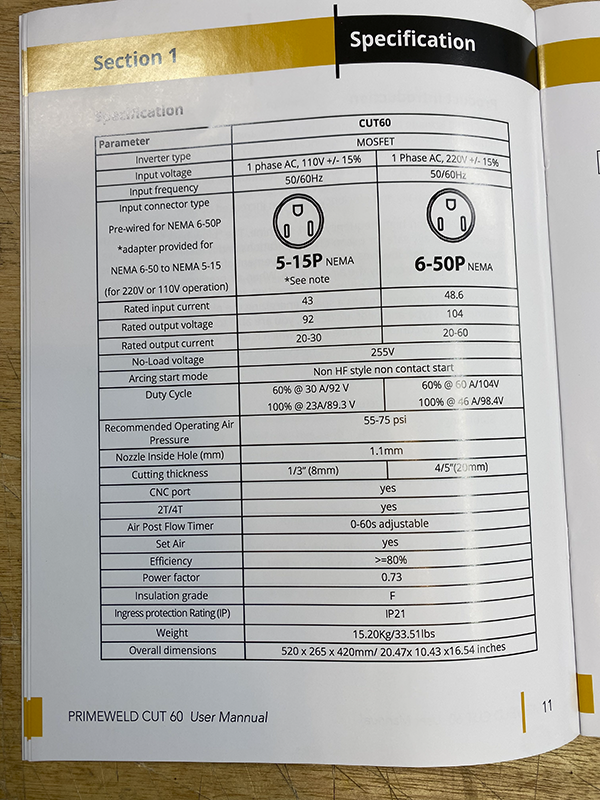

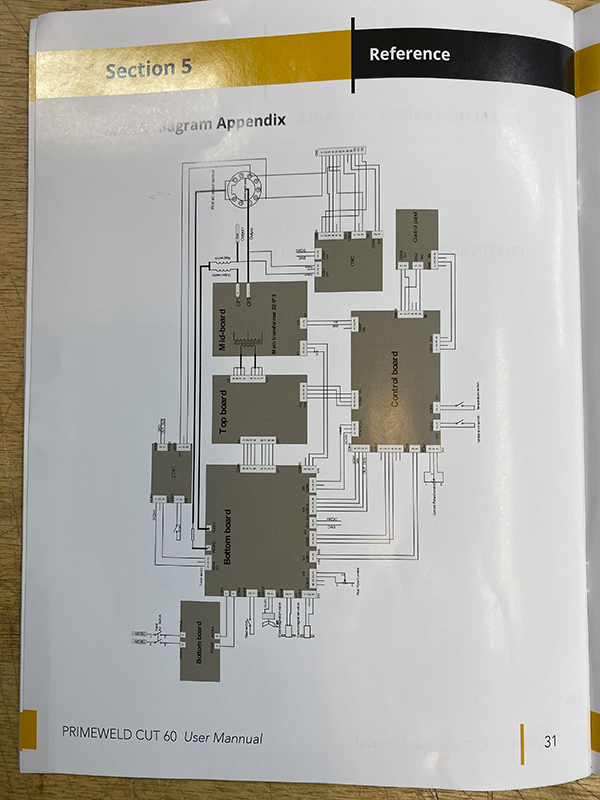

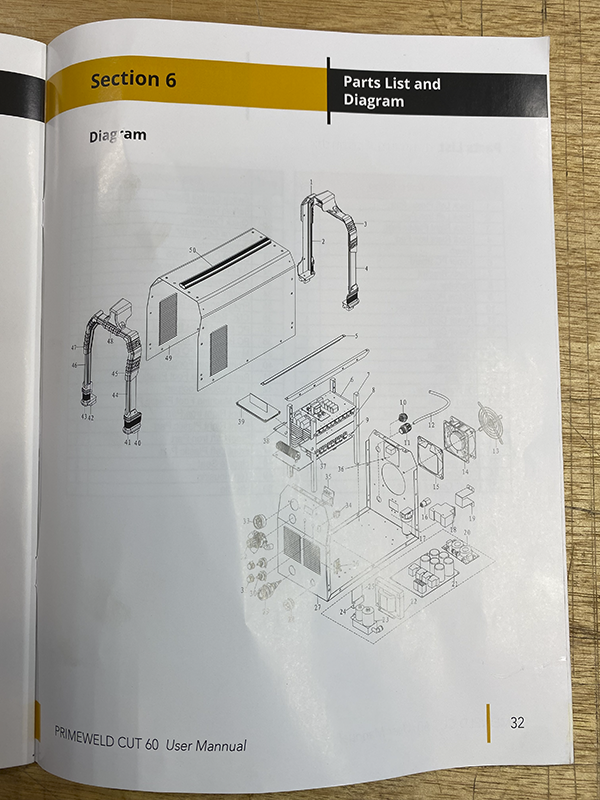

Starting with the manual, we have a lot of good information regarding the settings for the AMPS and PSI for each material and it’s thickness. I also appreciate that it had a full schematic of the internal parts. It’s one of the better product manuals I’ve seen with laminated glossy pages of color photos, graphic illustrations, and well written instructions. Much better than a basic paper manual that would easily rip if you spilt your favorite beverage on it.

As I said earlier, It came with everything you would need to get started.

Of course I highly recommend getting more consumables.

Speaking of consumables, they included some in the box!

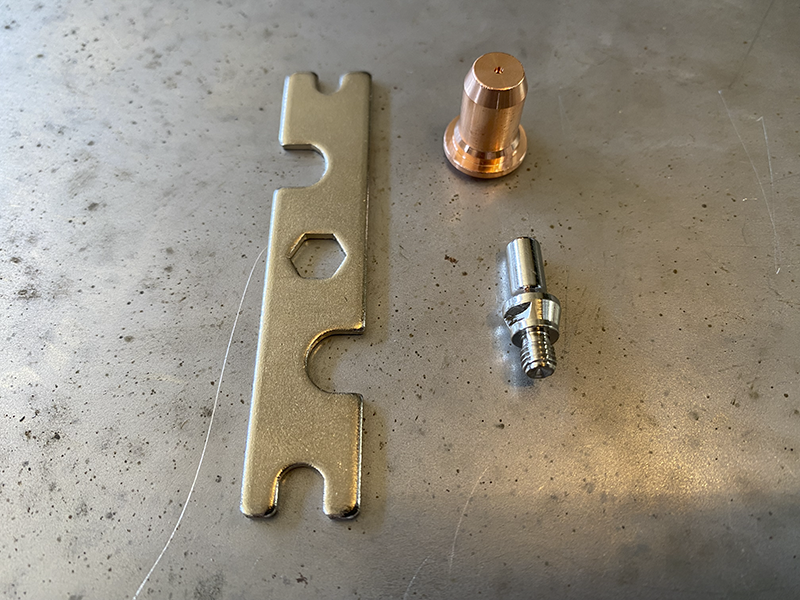

A tip, an electrode, and a wrench.

They also included a hand held mask incase you don’t have one.

Believe it or not, I do use it because it’s quicker and lighter to put over my eyes than to mess with the big welding helmet I have.

Below you see it disassembled with the included chipping/brush hammer.

They also included a 220V to 110V adapter which is handy for using at a remote location where 220V is not available. This would also be helpful if you were at a friends house without a 220V receptacle.

The ground clamp is pretty standard and If you’re looking for a nicer one you may want to upgrade it.

But it sufficed my needs and I really don’t have an issue with it. It clamps really well and I like that it has copper contacts for continuity. If it does give me problems I’m eyeballing the 400 Amp welding ground clamp at Harbor Freight. The cable has a decent wire guage and is 12 feet long.

The PrimeWeld Cut60 has a CNC port on the back and they have included the adapter for your CNC setup. The wiring diagram and instructions are included in the manual.

The IPT-60 Torch is one of the better ones with an reinforced polycarbonate mold incase you drop or step on it.

The torch is totally repairable and it’s fairly easy to replace consumables. The standoff or guide is two pronged and is a lot better for following straight edges for accurate cutting. The base of the torch swivels to alleviate any stress caused when contorting or angling the torch. The torch has a 20 foot rubberized heat resistant sheath that protects the wiring. I’m very impressed with the quality.

The PrimeWeld Cut60 Plasma Cutter itself has a robust case which is primarily metal with plastic accents. I don’t even think the plastic has anything to do with the construction as much as it has to do with the design. So that is a good thing. It was quite heavy and has a heavy duty handle which is more than capable of handling it’s own weight. All the dials, guages, and electronics are of good quality and function good. There are no leaks from the gas input as well. All the connections for wires were functional and secure. The quality control is good with PrimeWeld. One observation is the fan seems to run continuously while powered on. I would say this is a good thing but a little noisy.

When using anything that involves sparks, heat, or electricity it is always best to practice good PPE safety.

Which means a well ventilated room or garage, good rubber boots, fire retardant clothing, welding helmet or mask, and leather gloves are highly recommended. I would also stress to check your surroundings and check for rogue combustible tanks like propane or Coleman stove gas cylinders are not close. As well as any flammable materials like sawdust, trash, or flammable liquid chemicals. A good prepped area will prevent any disasters. When using a plasma cutter it is best to keep your torch cord out of the way of the cutting direction. It goes without saying but also any of your favorite limbs as well. Remember that the metal you are cutting is going to be red hot. Be careful of where you fling the piece you just cut with your slag hammer. Sometimes slag will cause the piece to fuse to the metal you just cut which requires you to use your slag hammer.

I started out cutting smaller to larger pieces. I recently acquired some heavy metal from a local plant that makes top secret equipment for NASA. I literally climbed into a huge barge with very large pieces precariously leaning on either side. I could’ve killed myself looking back on what I did.

I was climbing under and over large metal tubes that weighed hundreds of pounds. I was shocked they allowed me in the barge without any PPE gear. Well, we all live and learn eventually.

The first piece I cut was a piece of sheet metal at 18 guage. I followed the recommended settings for that guage and it cut like butter. I could easily see myself getting a CNC table and hooking the PrimeWeld Cut60 up to make anything from custom parts for automotive, construction, or decorative purposes.

The second pieces I cut were a 14 guage angle and flat steel bar. I may have had the settings too high or the PSI too low because the cuts were a little ugly. Nonetheless it did it’s job cutting them.

The third type was a 1/8″ mild steel bar which cut a little better. There was one breaker flip on this 1/8″ piece due to my 15 amp breaker. These cuts were done free hand without a guide. A guide is always recommended for a straighter cleaner cut.

The next piece I cut was a 1/4″ mild steel bar. This was also a clean cut but the machine struggled to cut it because of my 15 amp breaker. I think a 20 amp breaker would support the machine better on 110V. The breaker flipped 5 times while trying to cut the 1/4″ bar.

The PrimeWeld Cut60 shines on 220V and rightfully so.

I had some stainless steel that I wanted to try on the plasma cutter. I was careful to follow the guidelines, but I fear that this particular stainless steel was so hard that it affected the cut quality. However, I’m not concerned because I generally do not deal with that thickness. But I was impressed with the cut edge and how it kept my angle and design. A little flap disc cleaning and it was totally acceptable in my opinion.

Below you see a 3/4″ piece of hardened stainless steel plate. I slowely directed the plasma torch to cut in a jagged step pattern and it did a fine job. There was some residual slag but was easily cleaned up.

The PrimeWeld Cut60 Plasma Cutter is rated for 7/8″ which I didn’t have that thickness on hand, but I did have another hardened stainless steel bar that was 1″. It cut it but it looked more like a burn than anything. I had to give it some good whacks with my hammer to persuade it to come apart due to all the slag.

My truly honest opinion of the tool is buy it! This is the first plasma cutter I have owned. So I don’t know if there is a better one on the market. However, I was extremely pleased with everything especially the 3 year warranty. This is a luxury you need in your shop. The abrasive cutting disks are not cheap when you consider the faster wear. There are other concerns with health and risk of injury as well.

An Acetylene torch is also dangerous due to the risk of a gas leak. It is also pricey to keep the tanks regularly filled.

Well I hope you enjoyed this article and found the information useful. Be sure to like and subscribe on my YouTube channel and watch out for the next episode on making my plasma table.

Don’t forget to check out my YouTube episode on the unboxing, setup, and review of the PrimeWeld Cut60 Plasma Cutter. Any link on the YouTube description, or here on my blog is an affiliate link. I do appreciate your support if you use them.

YouTube Episode:

Tools Used: (Affiliate Links)